| Plastindia Foundation has instituted "Plasticon

Awards" recognizing innovation & excellence

and these awards are presented to those who have

made path-breaking contribution for development

of Indian Plastics Industry. The Awards germinate

from a perceived need to honour and recognize excellence

of Organizations, Individuals, Companies and Institutions

actively involved in research and development of

plastics, and related products and honour their

path-breaking contribution to the overall development

of Indian Plastics industry. A write up on the Innovative

Product Award Winner - Indian Institute of Management,

Ahmedabad

Passive-dew-condenser is a device designed to

extract moisture from humid air without the use

of external energy. Under a clear sky at night

, the condenser surface gets cooled simply by

radiative exchange with sky, becoming colder than

the dew-point of the surrounding humid air. When

that happens some of the vapour contained in the

air condenses on its surface. The condenser surface

is set at an angle from the horizontal to permit

draining by gravity. When conditions are favorable

condensation could occur over good part of the

night yielding significant amount of water which

has been tested and found potable. Water only

needs to be filtered and sterilized by UV light

or boiling. Samples of dew water from a part of

Kutch are shown in Figure 1.

Figure 1: Dew water from Kothara - Kutch obtained

using passive dew

In the interior regions of India,

dew occurs only (or mostly) in winter months.

In coastal arid regions such as Kutch in Gujarat,

dew occurs over a period of 8 months from October

to May. In fact, measurements have shown that

dew occurs more frequently and in larger quantity

in summer months compared to others. It also happens

that good quality water is scarce in these regions.

Plastics has been successfully used to develop

dew harvest systems for people living in coastal

villages of Kutch to enable them to harvest dew

and use it as a supplementary source of water.

Suitably designed large cost-effective dew condensers

can enable humans too to extract moisture from

air. Plastics appear to be the most promising

material to achieve this. Besides the plastics,

metal sheets used for roofing can also be used

as condensers.

Development of condensers

The development work was spread over a three

year period and has passed through three stages.

In the first stage systematic measurement of daily

dew fall was made at Kothara, Kutch over a one

year period. In the second stage test condensers

were made and tried for one year. In the third

stage pilot scale condensers were made and tried.

Test

Test condensers were made using several materials

including polyethylene (PE) film, polyethylene

mixed with titanium-oxide and barium-sulfate (PETB)

film, fiber reinforced plastic (FRP) sheet and

poly-carbonate sheet. The PETB film was first

developed and tried for dew condensation in France

by Nilsson, Beysens and others. The film was made

to specifications. Galvanized iron and aluminum

sheets were also included in the trials.

Condensers made of plastic

A condenser has three components: a panel, mounting

frame and collection accessories. The panel is

made of two sheets bonded together with adhesive.

The sheet on top is made of material being tested

for its suitability to construct condensers, indicated

above. This sheet is insulated with styrene foam

sheet of 25mm thickness on the underside. Panels

are squares of 1x1 m. Panel is mounted on metal

frame made of welded angles. The collection accessories

(channel and tube) are also supported on the frame.

The panel is mounted with a 30 angle with the

horizontal. Flow is channeled via a flexible rubber

tube into a plastic bottle securely placed on

the ground.

All the test condensers were installed

in a coastal village - Kothara, Kutch - and daily

dew condensation was measured for one whole year.

Figure 3 shows the test site at Kothara.

Measurements showed that PETB

film gave the highest yield {Table 1(a)}

:

Monthly dew yield from north oriented Test condensers

(Kothara-04-05)

| Month |

GI |

Aluminium |

PETB |

| |

(ml) |

(ml) |

(ml) |

| Oct |

1060 |

1145 |

2620 |

| Nov |

320 |

260 |

830 |

| Dec |

370 |

245 |

345 |

| Jan |

195 |

140 |

135 |

| Feb |

2255 |

1530 |

2085 |

| Mar |

5285 |

2950 |

4920 |

| April |

2405 |

1090 |

3052 |

| May |

1498 |

435 |

2055 |

| Total |

13388 |

7795 |

16042 |

Table 1(b) : Dew nights from

north oriented condensers (Kothara-04-05)

| Month |

GI |

Aluminium |

PETB |

| |

(No.) |

(No.) |

(No.) |

| Oct |

9 |

8 |

12 |

| Nov |

4 |

3 |

5 |

| Dec |

3 |

2 |

3 |

| Jan |

2 |

1 |

2 |

| Feb |

12 |

11 |

12 |

| Mar |

28 |

20 |

26 |

| April |

18 |

8 |

12 |

| May |

16 |

5 |

12 |

| Total |

92 |

58 |

94 |

Trials in Kutch confirm the findings of Nilsson

and Beysens from France. Metal sheets give lower

yields specially the new commercial aluminium

sheets. FRP and polycarbonate also give good yields

but being expensive these are not suited for suited

for large practical harvest systems.

Pilot

After analysis of the year-long measurements,

PETB was selected to make larger pilot condensers

for further trial. Figure 4 shows the pilot PETB

condenser. It consists of two basic modules, each

of 9m2 surface area or 3x3

m in size. The condenser surface is made of PETB

sheet of 400 micron thickness. Condenser is insulated

in the same manner as were the smaller ones. The

condenser modules are placed on a sand bed that

has a slope of 30o from the horizontal.

Commercial

Two types of models are ready for commercialization.

The smaller model is for individual families living

in coastal arid areas. It is called Dew Family-20.

The larger model is for communities and for commercial

bottling plants. It is called Dew Community-X.

Dew Family - 20 is sized for an average output

of about 20 liters per day during the season.

It will be built using 300 m2 plastic

(PETB) film. Total collection of dew water over

the season of 8 months would be approximately

5000 liters. The system will also harvest rain.

The systems could be installed at or near the

user's home (Figure 5).

Dew-Community systems will be larger and will

serve a community by bottling dew and selling

at affordable price locally. These will be built

on 'waste-land' and other locations along the

coast.

Dew harvesting be an attractive option in areas

where (a) dewfall occurs frequently, in appreciable

quantity over a long season and (b) where there

is shortage of potable water.

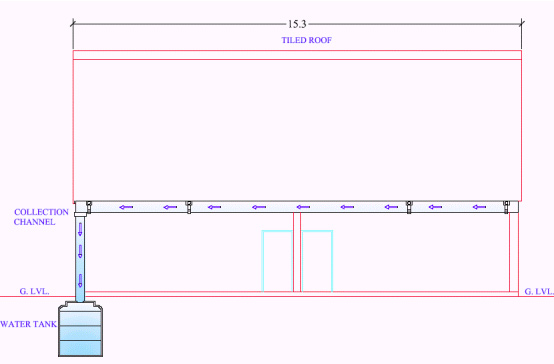

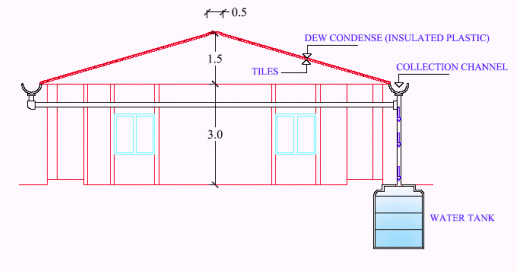

Figure 5(a) Roof over roof

dew harvest system On a tiled roof house - Front

view

Figure 5 (b) Roof over roof dew harvest system

On a tiled roof house - side view

|