|

Wire and cable industry heavily depends upon

PVC for jacketing applications due to economic reasons. PVC is more

economical and more versatile as compared to PE - at least in power

cable system, which incidentally has almost 2/3rd share of the wire

& cable business. However, PVC, due to modest electrical properties

as compared to PE, has been gradually losing market share to PE

over the last two decades. PVC insulation not only has inferior

electrical properties, but has chances of higher electrical failure

at lower temperatures when compared to PE. Therefore, it is no wonder

that PE has taken over from PVC in the high tension power cable.

PVC, on account of its polarity, also does not have resistance to

high frequency electrical current that is required in telecommunication

cables. One of the major reason for a shift from PVC to PE is the

environmental disposal of PVC, which contains heavy metal as a heat

stabilizer. The shift is more in Europe and is also taking place

in North America. Asia, however, is slow in shifting to PE and still

predominantly uses PVC.

The wire & cable market can be basically classified into the

following:

Power wires and cables:

Power wires and cables:

|

Power transport and distribution networks Dry-insulated, armoured

or unarmoured cables:

# High and very high voltage,

# Medium voltage. |

|

Low-voltage cables, aerial or underground for distribution networks

and connection. |

|

Domestic wires and cables and appliance cords for mobile apparatus

with a 750 V maximum rated voltage. |

|

Industrial cables, (maximum rated voltage 1000 V) for industrial

equipment and power supply of mobile apparatus. |

Special cables and wires for intended purpose:

Special cables and wires for intended purpose:

|

Wires and cables intended for electrical equipment fitted in automobiles,

aircrafts, lifts, ships, machine tools, railway materials, mines,

handlings, petrochemical industry, oil equipments, iron and steel

industry, welding, etc. |

|

Precision and data cables for computer equipments, electronics

and automatic control instruments. |

|

Heating cables. |

Telecommunication wires and cables:

Telecommunication wires and cables:

|

Cables for aerial and underground medium and long distance lines. |

|

Cables for exchange area networks underground and aerial junctions,

subscribers cables. |

|

Telephone cords. |

|

Cables for private installations. |

Submarine and underwater cables:

Submarine and underwater cables:

|

Cables for power transport. |

|

Cables for telecommunication. |

Connection accessories for power cables:

Connection accessories for power cables:

|

Low-voltage: connections, branching. |

|

Medium voltage terminations. |

|

Medium voltage plug-in terminations: separable connectors, bushings. |

|

Medium voltage connections and branching for dry or paper insulated

cable, lapped, injected. |

|

Prefabricated medium voltage connections for dry-insulated cable. |

|

High and very high voltage: terminations, connections. |

Market shares are roughly estimated at:

|

65% for power cables (50% for low-voltage and 15% for medium and

high-voltage) |

|

25% for telecommunications |

|

10% for other cables |

Polymer properties:

Polymer properties:

Polymer properties essentially required for cables are:

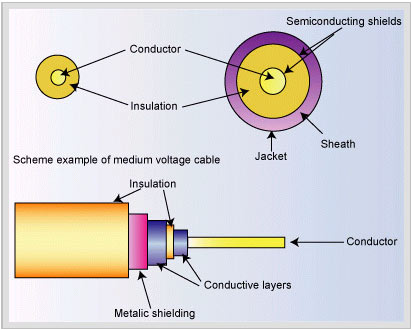

All the layers of a cable covering are not insulating but some of

them are semiconductive or conductive to create EMI shielding. The

following figure shows some required properties for the used polymers.

Some of them deserve certain details:

|

Electrical properties: apart from resistivity

or conductivity, the dielectric rigidity; for example, is important

to avoid the risks of breakdown and the dielectric constant |

|

Mechanical properties: generally, flexibility

is required with fair mechanical performances.

For outside covering layer specific characteristics can be specified

such as high mechanical performances, light and/or ozone resistance

for outdoor or industrial applications, abrasion and tear resistances

for industrial applications. |

|

Durability: Long-term ageing is nearly always

required and there are often other requirements for the covering

layer concerning UV or ozone ageing, moisture or water immersion

for submarine cables, and oil resistance for industrial applications. |

|

Fire behaviour: ignition, smokes (opacity, toxicity

and corrosivity). |

|

Cost: adapted to the applications. |

Figure 1 shows the principle of low-voltage wires and two examples

of cables.

Figure 1: Principle of low-voltage wires and cables |

Figure 2 shows the principle of cable ribbon and bundle.

| Polymer |

Dielectric constant |

| Foam Polyethylene |

1.6

|

| Fluoropolymers |

2.0

|

| Polypropylene |

2.1

|

| Polyethylene |

2.3

|

| Butyl rubber |

2.3

|

| SBR |

2.9

|

| Polyamide |

3.0

|

| Silicone Rubber |

3.2

|

| PVC |

4.0

|

| Neoprene |

5.0

|

As shown in the following figure, PE is the most consumed polymer

(near 60%) under thermoplastic and thermoset (PEX) states, and also

foamed PE (2%). PVC is the second (roughly 30%) and the others are

rubbers, PP, TPEs, Polyamide, Polyurethane, Silicone, fluoropolymers.

| Total consumption share inthe Wires &

Cables sector |

| Polymer |

%

|

| LDPE |

5

|

| HDPE |

2

|

| LLDPE |

2

|

| PA |

2

|

| PVC |

8

|

Apart from PVC, PE and its copolymers, other polymers are used

for special applications justifying their higher cost. They are:

|

Rubbers. |

|

Fluoropolymers for high temperature and/or chemical resistance. |

|

TPEs: special grades are marketed, eventually crosslinked after

extrusion. |

|

Special polyurethane elastomers for telephone wire insulation. |

|

Silicone cables for outside projectors, street lighting, drying

ovens, convectors, electric heating. |

|