|

Water Assisted Injection Moulding (WAIM) is a new

development in the field of Injection Moulding and said to be an

alternative to Gas Assisted Injection Moulding (GAIM). Using this

process, Tubular hollow parts and Rod shaped products can be manufactured

cost effectively.

This idea of Injection of Fluids (Water or Oil)

was proposed in 70’S but at that time, the use of water did

not succeed satisfactorily, due to difficulty in achieving high

flow rates and pressure.

Recently, IKV (Institution for Kunststoffverarbeitung),

Germany in association with finders Anglagentechnik has developed

a Proto type production line (Demonstration Plant ) and carried

out water injection successfully.

Benefits of WAIM (in comparison with GAIM)

Benefits of WAIM (in comparison with GAIM)

|

Reduce

cooling times, thus reducing cycle time |

|

Permits manufacture

of parts with large diameters |

|

Wall thickness

of the parts can be minimized. |

During demonstration of the WAIM process, for a

test part of 10 mm diameter the cycle time was found to be reduced

from 60 to 10 sces and wall thickness was reduced from 1.5 to 1

mm in comparison to the corresponding GAIM.

A PP based Charge air-pipe section with 60mm diameter

and 400mm long was produced with a cycle time of 50 seconds.

|

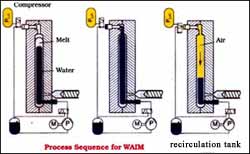

Process Principle

Process Principle

The Principle of WAIM is similar to sandwich

injection moulding. The process can be easily understood from

the figure and the steps involved are as below:

1.Injection of melt

The Quantity of melt injected should be less

than the total volume of cavity.

|

|

2.Injection of water with one or more Hydro

pumps

The injection of water takes place so rapidly in

such a way that,

|

Water does

not evaporate and, |

|

There is

no hydraulic degradation. |

The injected water in the melt forms a cavity by

the same principle as GAIM i.e. it forms a hollow cave by displacing

the molten melt in to spaces of the mold that have not yet been

filled.

At the transition, between waterfront and melt,

a thin plastic membrane is solidified, and acts like a displacing

piston on the molten core, pushing the polymer melt further. Thus

hollow body is formed.

Compared to gas used in GAIM, water provides better cooling effect

and thus leads to shorter cooling and cycle time.

3.Water is forced out of the part by compressed air.

The water can be recirculated via a storage tank.

Conclusions

Conclusions

WAIM can be used for production of certain parts

(eg. Ducts) that are not feasible with GAIM. Thus some limitations

of GAIM process creates opportunities for WAIM, as this process

offers cost reductions.

But the most important task is performance requirements

in balancing and process sequences in the process of water injection.

Further investigations and research works are going on at IKV to

improve the process.

|