Shape Memory Polymers (SMP) are polymeric smart materials that have the ability to return from a deformed state (temporary shape) to their original (permanent) shape induced by an external stimulus (trigger), such as temperature or light, change in electric or magnetic field or a change in pH. Once the permanent shape has been manufactured by conventional methods, the material is changed into another, temporary form by processing through heating, deformation, and finally, cooling. The polymer maintains this temporary shape until the shape change into the permanent form is activated by a predetermined external stimulus. The new materials allow deformations between permanent and temporary shape of up to 400%.

In 1930, scientists discovered specific metallic compounds exhibit the ‘shape memory’ effect when heated above a transition temperature. Since then shape memory alloys (SMAs), such as the nickel-titanium alloy Nitinol, has found uses in actuators and medical devices such as orthodontic wires that self-adjust and stents for keeping blood vessels open. However, despite their broad range of applications, SMAs are expensive, non-degradable and in many cases lack biocompatibility and compliance, only allowing for a deformation of about 8% for Ni-Ti alloys. Hence, shape memory materials, which take one form at a certain temperature and transform into another shape when heated, are not new, but until now, SMPs were not used in medical devices or proved to be biodegradable. The new SMPs have recently been used in intelligent biomedical devices and industrial applications for their ability to change shape under a predetermined stimulus. The new ‘smart’ plastic is composed of two components with different thermal characteristics, oligo(e-caprolactone)diol and crystallisable oligo(?-dioxanone)diol, each already used separately in clinical applications such as drug delivery. The biodegradable multiblock copolymer features two block building segments; a hard segment and a ‘switching’ segment, which are linked together in linear chains. The higher-temperature shape is the plastic’s ‘permanent’ form, which it assumes after heating. Certain classes of shape memory polymers are biodegradable, offering the option to develop temporary implants. After the implant has fulfilled its intended use and healing/tissue regeneration has occurred, the material degrades into substances which can be eliminated by the body, thus allowing full functionality to be restored without the necessity for a second surgery to remove the implant in order to avoid long term negative effects like inflammation.

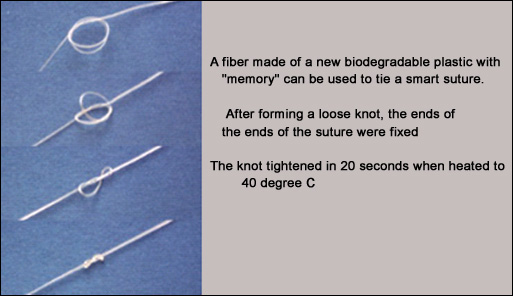

SMP for surgical sutures

Surgical sutures are used by surgeons to close a wound or to join tissues after they have been severed by injury or surgery. They are generally divided by their biostability into absorbable and non-absorbable sutures and by their design into monofilament and multifilament (braided) surgical sutures. Commonly used sutures exhibit significant drawbacks- they cannot seal the punctured tissue completely, multifilament threads create a higher risk of bacterial transport or migration and higher tissue reactivity due to their braided design. Also, physicians concerned with poor knot security, need to tie multiple securing knots, which is time consuming and particularly in minimally-invasive endoscopic procedures, difficult. SMP based absorbable surgical sutures have the potential to address current unmet needs. Among other features, they may allow for easier application and securing of sutures. Further, they may be programmed to tighten over a defined period of time to ensure optimal tissue approximation. Researchers made sutures from SMPs by heating fiber of their ‘shape shifting’ material to 50°C. They were then stretched to three times their length and cooled to room temperature. These extended fibers were then used to loosely stitch a wound on a rat. When the suture was heated to 41°C (just above body temperature), the thread tightened and closed the wound, applying just the right amount of pressure (0.1 N). Later, after the wound is healed, the material is designed to dissolve and is harmlessly absorbed by the body.

Shape Memory Polymer Stent

Currently, coronary stent technology relies on metals such as stainless steel and cobalt-chromium alloys (CoCr), materials that remain permanently in the body and can cause severe complications such as thrombotic occlusions (obstructions) and/or restenosis (recurrent narrowing of openings), even when used with sophisticated drug coatings.

Researchers have shown the feasibility of SMP application in medical stents by getting a long fiber of the material to transform into a corkscrew shape, typical of a stent. Such stems could be compressed and fed through a tiny hole in the body into a blocked artery. The body’s warmth would trigger the polymer’s expansion into its original shape, and over time it would dissolve in the body.

Researchers at the Georgia Institute of Technology are developing unique polymers, which change shape upon heating, to open blocked arteries, probe neurons in the brain and engineer a tougher spine. These so-called shape-memory polymers can be temporarily stretched or compressed into forms several times larger or smaller than their final shape. Then heat, light or the local chemical environment triggers a transformation into their permanent shape. The focus of the team has been to optimize these polymers for many different biomedical applications, studying how altering the chemistry and structure of the polymers affects their chemical, biological and mechanical properties. The team has designed a shape-memory polymer stent that can be compressed and fed through a tiny hole in the body into a blocked artery, just like a conventional stent. Then, the warmth of the body triggers the polymer’s expansion into its permanent shape, resulting in natural deployment without auxiliary devices.

SMPs have potential applications as intravenous cannula, self-adjusting orthodontic wires and selectively pliable tools for small scale surgical procedures where currently metal-based shape memory alloys such as Nitinol are widely used. Another application of SMP in the medical field could be its use in implants, e.g. minimally invasive (trough small incisions or natural orifices) implantation of a device in its small temporary shape which after activating the shape memory by e.g. temperature increase assumes its permanent (and mostly bulkier) shape.

|

|