The objective of flame retardant

thermoplastics is to increase the resistance

of a material to ignition and, once ignited,

to reduce the rate of flame spread. The product

does not become non-combustible, but the use

of a flame-retardant additive may prevent a

small fire from becoming a catastrophe.

The Burning Process of Plastics.

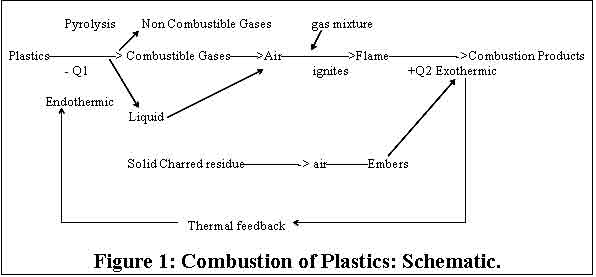

The combustion of plastics is a process comprising

many steps. A simplified schematic representation

of the various phenomena, which take place during

the combustion of plastics, is shown in Figure

1

Three stages are necessary to initiate the actual

combustion process:

• Heating

• Decomposition

• Ignition

of the polymer

Heating

The solid plastic is heated by an external

source or by “ thermal feedback” as shown in

figure 1. In this initial phase, thermoplastics

tend to soften or melt and start to flow.

Decomposition

Decomposition is an endothermic process in which

sufficient energy must be provided to overcome

the high binding energies of the bonds between

individual atoms (between 200 and 400kJ/mol.)

and to provide any necessary activation energy.

As the individual plastics differ in structure,

their decomposition temperature ranges vary

within certain limits. Table 1 gives the range

of decomposition temperature for some plastics

and for cellulose (a natural polymer).

Table 1: Range of Decomposition Temperature

of Some Thermoplastics

Thermoplastic

|

Decomposition

Temperature (Td Deg C)

|

Polyethylene

PE |

340-440 |

Polypropylene

PP |

320-400 |

Polystyrene

PS |

300 – 400

|

Polyvinyl

Chloride PVC |

200 – 300

|

PolytetrafluoroethylenePTFE

|

500 – 550

|

Polymethylmethacrylate

PMMA |

180 – 280

|

Polyacrylonitrile

PAN |

250 – 300

|

Polyamide

6 PA6 |

300 – 350

|

Cellulose

|

280 – 380

|

In most cases, decomposition

occurs via free radical chain reactions, initiated

by traces of oxygen or other oxidizing impurities,

which are trapped in all plastics during manufacture.

The oxidative degradation of polymers usually

proceeds via the formation of hydroperoxide

groups whose decomposition leads to highly reactive

species such as H & OH radicals and thus

to chain branching. These radicals are responsible

for flame spread in the combustion process.

Ignition

The flammable gases formed by pyrolysis,

mix with atmospheric oxygen, and reach the lower

ignition limit and are either ignited by an

external flame or, if the temperature is sufficiently

high, self-ignite. The flash ignition temperature

(FIT) and self-ignition temperature (SIT) are

given in Table 2.

Table 2: FIT and SIT of Some Thermoplastics.

| Polymer

|

FIT

Deg C |

SIT

Deg C |

| PE |

340

|

350

|

PP

|

320

|

350

|

PS

|

350

|

490

|

PVC

|

390

|

450

|

PTFE

|

560

|

580

|

ABS

|

390

|

480

|

PMMA

|

300

|

430

|

PAN

|

480

|

560

|

PA

6 |

420

|

450

|

PA

66 |

390

|

530

|

PU

Foam |

310

|

415

|

Cotton

|

210

|

400

|

Ignition depends on numerous

variables such as oxygen availability, temperature,

physical and chemical properties of polymer.

The reaction of the combustible gases with oxygen

is exothermic and if sufficient energy is available,

overrides the endothermic pyrolytic reaction

and initiates flame spread.

Flame Spread

The exothermic combustion reaction

reinforces pyrolysis of the polymer by thermal

feedback and fuels the flame at an increasing

level.

Another factor, which determines the extent

of flame spread, is the heat of combustion of

the polymer. The heat of combustion of various

polymers are compared with those of cotton and

cellulose in Table 3.

There is no correlation between the heat of

combustion and combustibility of a material.

An example of this is extremely flammable celluloid,

which has a heat of combustion of only 17,500

kJ/Kg.

Concurrent with the extremely

rapid gas phase reactions, various slower oxygen-

dependant reactions also take place. These give

rise to soot and carbon-like residues and take

place partly in a condensed phase with glow

or incandescence.

Table 3: Heat of combustion of various

plastics and natural polymers

Polymer

|

Heat

of Combustion, kJ/Kg |

PE

|

46,000

|

PP

|

46,000

|

PIB

|

47,000

|

PS

|

42,000

|

ABS

|

36,000

|

PVC

|

20,000

|

PMMA

|

26,000

|

PA

6 |

32,000

|

Polyester

resin |

18,000

|

Natural

rubber |

45,000

|

Cotton

|

17,000

|

Cellulose

|

17,000

|

Celluloid

|

17,000

|

Burning Behavior of Polyolefins

Polyolefins burn hesitatingly

at first with a small bright blue flame (PE

LD and PE HD) and subsequently, with a bright

yellow flame, which continues to burn after

removal of the ignition source. The fire gases

and smoke vapors smell of wax and paraffin.

This odor is pungent in the case of PP. After

the flame is extinguished a smell of dead candle

remains. In the absence of oxygen, PE starts

to degrade thermally at about 300 Deg C. In

the presence of Oxygen, thermal degradation,

thermal degradation sets in at 150 Deg c with

the color changing from white through brown

to black. PP undergoes thermal degradation more

easily than PE particularly when oxygen is present.

Flame Retardant Polyolefins

The primary additives used

to accomplish the objective of imparting flame

retardancy to Polyolefins are halogens and phosphorus

containing organic compounds. Antimony oxide

is generally required as a synergist for halogen

compounds. Inorganic compounds containing high

concentration of water of hydration such as

alumina trihydrate and magnesium hydroxide are

also used. The type of flame retardant and quantity

needed for polyolefin applications are largely

governed by cost/performance ratio.

Manufacture of Flame Retardant Polyolefins

World over flame retardant

polypropylene compounds are finding increasing

use in injection molding and fiber applications.

In this application note, we would focus only

on FR/PP compounds for injection molding applications.

FR/PP compounds are best made on a twin – screw

compounding extruder having a l/d of 40:1 and

equipped with side feeder arrangement for dosing

FR additives. Gravimetric dosing units are needed

for accurate metering of FR and other additives

in to the polymer matrix.

Tailor-made formulations can be prepared depending

on end –user specifications.

For injection molding application, a typical

temperature profile in the injection-molding

machine is

Zone 1or hopper

end |

Zone 2 |

Zone 3 |

Zone 4 |

Nozzle |

Melt

Temperature |

165 |

200 |

210 |

215 |

225 |

220 |

This temperature profile is

subject to change depending on the flow length/thickness

ratio of the product and capacity of the machine.

FR additives affect the metal surface in the

hopper, barrel and screw of the compounding

and molding machines. Hence it is recommended

to purge the machines with high flow LLDPE/LDPE

or with any commercially available purge resins.

Testing of Flame Retardant Plastics

Flame retardant Polyolefins

are frequently designed to meet specific flammability

tests. The laboratory tests used most frequently

for thermoplastics are described here.

Ease of Ignition: Oxygen Index

Ease of ignition may be defined as

the facility with which a material or its pyrolysis

products can be ignited under given conditions

of temperature and oxygen concentration. This

characteristic provides a measure of fire hazard.

ASTM D 2863-77 describes the test protocol for

measuring oxygen index.

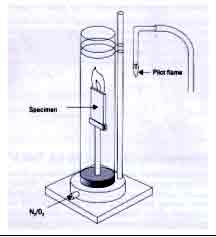

The oxygen index test employs

a vertical glass tube 60 cm high and 8.4 cm

in diameter, in which a clamp at its bottom

end holds a rod or strip specimen vertically.

A mixture of oxygen and nitrogen is metered

into the bottom of the tube, passing through

a bed of glass beads at the bottom to smoothen

the flow of gas, providing a specific environment

for the sample. The sample is then ignited at

its upper end with a hydrogen flame, which is

then withdrawn. The sample then burns like a

candle from the top down. (Figure 2). The atmosphere

that permits steady burning is then determined.

The oxygen index or the limiting

oxygen index, is the minimum percent of oxygen

in an oxygen-nitrogen mixture that will just

sustain burning for 2 inches or 3 minutes, whichever

comes first.

2. Flammability Testing for Electrical

and Electronic Materials UL94

The most widely accepted flammability

performance standards for plastic materials

are UL (94) ratings designed by Underwriter's

Laboratories Inc., USA . These ratings are intended

to provide an indication of a material's ability

to extinguish a flame once ignited. Several

ratings can be applied based on the rate of

burning, time to extinguish ability to resist

dripping and whether or not drips are burning.

Each material tested may receive

several ratings based on color and/or thickness.

When specifying a material for an application,

the UL rating should be applicable for the thickness

used in the wall section in the plastic part.

The UL rating is "always"

reported with the thickness. UL rating

reported without specifying thickness is insufficient

and can be misleading.

The UL-94 has four separate sections containing

different test methodologies and these are described

hereafter: -

UL 94 HB Horizontal

Burning Test Procedure

In general, HB materials are not recommended

for electrical properties except for mechanical

and/or decorative purposes. Sometimes misunderstood:

materials that are not meant to be FR materials)

do not automatically meet HB requirements. UL

94 HB is, although the least severe of flammability

classification has to be checked by testing

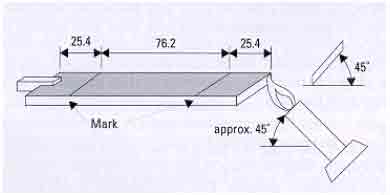

Test Protocol

The test places a sample 127mm

(5.0 inches) long and 12.7mm (0.5 inches) wide

in a horizontal position over a standard Bunsen

burner. The test measures burn rate in mm/min

or inches/min.

A sample, should not have a burn rate exceeding

76mm/min for thickness less than 3mm

A schematic of the test protocol is shown in

Figure 3.

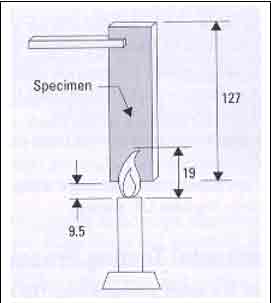

• UL 94 V0, V1 & V2 Vertical

Testing Procedure

The vertical tests (Figure

4) take the same specimens as are used for the

HB test. Burning times, glowing times, when

dripping occurs and whether or not the cotton

beneath ignites are all noted. Framing drips,

widely recognized as a main source for the spread

of fire or flames, distinguish V1 from V2

Test Protocol

A sample 127mm (5.0 inches)

long and 12.7mm (0.5 inches) wide is suspended

vertically over a Bunsen burner flame. The thickness

generally adopted is 0.8mm, 1.6mm or 3.2mm.

The distance between the test specimen and cotton

beneath is 300mm or 12 inches. A 20mm methane

flame is applied for two, ten second ignitions.

Different classifications are accorded depending

on the burning characteristics of the material.

• A V0 material

may not burn for over 10 seconds after the removal

of the flame. It may also not have flaming drips

which can ignite the cotton placed beneath the

test specimen

• A material rated V1 may burn for

a period not exceeding 30 seconds and not have

any flaming drips

• A material rated V2 may also not

burn over 30 seconds, but may have following

drips which ignite the cotton

• A material which does not pass

any of these categories is rated as " Failure

"

UL94 5V, 5VB & 5VA Ratings

These are high performance ratings and are

not considered here in this paper

Summary

A summary of the UL 94 rating categories is

provided below: -

#

|

Criteria

Conditions time in sec |

94V0

|

94V1

|

94V2

|

1

|

After flame

time for each individual specimen |

<

10 |

<

30 |

<

30 |

2

|

Cotton ignited

by flaming drips or particles |

No

|

No

|

Yes

|

• Flame

Spread.

Flame spread, or the rate of travel

of a flame front under given conditions of burning,

is a measure of fire hazard. The spreads of

flame along the surface of a material can transmit

fire to more flammable materials in the vicinity.

The Underwriters Laboratories

25 ft.tunnel test developed by Steiner is perhaps

the most widely accepted test for surface flame

spread. The test requires a specimen 25ft long

and 20 in. wide, mounted face down to form the

roof of a 25 ft-long tunnel 17 ½ in.

wide and 12 in. high. The fire source, two gas

burners 1 ft from the fire end of the sample

of select – grade red oak flooring would spread

flame 19 ½ ft from the end of the igniting

fire in 5 ½ Minutes +/- 15 sec. The end of the igniting

fire is considered as being 4 ½ Ft from the burners, this flame

length being due to an average air velocity

of 240+/- 5 min. Flame spread classification

is determined on a scale on which asbestos –

cement board is zero and select-grade red oak

flooring is 100.

• Smoke Measurements.

Smoke or smoke density is defined

as the degree of light obscuration produced

from the burning of a material under a given

set of combustion conditions. This characteristic

provides a measure of fire hazard in that occupants

have a better chance of escaping from a burning

structure if they can see their way. ASTM E662-83

“Specific Optical Density of Smoke Generated

by Solid Materials” is used to determine the

smoke density characteristics of a material

under controlled laboratory conditions.

The smoke density chamber test

is used to determine the specific optical density

of smoke generated within a closed chamber due

to non-flaming pyrolytic decomposition and/or

flaming combustion. The non-flaming mode employs

an electrically heated radiant energy heat source

with an irradiance level of 2.5W/cm^2. For the

flaming mode, a six –tube burner, fuelled with

a mixture of propane and air, is used in combination

with the radiant heat to apply a row of equidistant

flamelets across the lower edge of the specimen

and into the sample trough.

Light transmission measurements

are used to calculate the specific optical density,

which is derived from a geometrical factor associated

with the dimensions of the test chamber and

specimen, and the measured optical density,

a measurement characteristic of the concentration

of the smoke. The photometric scale used to

measure the smoke generated in this test is

similar to the optical density scale for human

vision.

(By Product

Application & Research Centre, Reliance

Industries Limited, Mumbai)

|