Electric machines have significantly improved the energy efficiency of the injection molding industry over the last 20 years. New ways to save energy and keep costs down during times of rising energy costs is the need of the hour. Melt-stream heating, particularly of the barrel, presents a strong prospect. Typically, 30-70% of the power consumed by band-heaters is wasted by radiation and convection to the surrounding environment. Eliminating these losses will reduce specific energy usage and allow machines to be pre-heated faster using the same power delivery infrastructure, thereby reducing downtime to increase productivity.

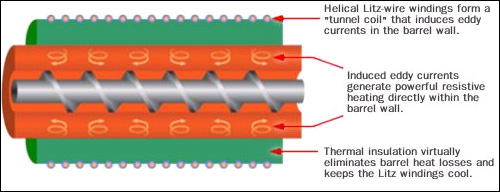

Inherent characteristics of band-heaters also hamper temperature control response, limiting improvements in part-to-part quality uniformity and efforts to minimize change-over times. A band heater’s temperature must first rise above that of the barrel before the barrel can be heated, and conversely, a band-heater’s temperature must fall below that of the barrel before it can be cooled. The thermal mass of band-heaters and the thermal contact resistance between them and the barrel, therefore significantly increase the thermal inertia of the melt stream. The recent introduction of lower weight radiant heating elements provides an opportunity for improvement. Another new technology that offers significant advantages is noncontact induction. Barrel heating using helical induction coils has been considered for decades, but was poorly applied. Past efforts often used inefficient low-frequency power supplies and always put the coils in direct contact with the barrel, undermining the compelling advantages of induction. Heat generated in the barrel was still allowed to escape to ambient and the coils’ thermal mass wasn’t removed from the equation. Contact with the hot barrel also increased the coil’s electrical resistance & reduced efficiency gains.

Xaloy nXheat™ induction barrel heating (patent pending) sharply cuts energy costs and improves temperature control for better quality and less scrap compared with conventional heater bands. The nXheat ™ barrel heating solution (patent-pending) uses an optimized high-frequency power supply and a thermal insulating layer interposed between the barrel and coils to address the above issues and exploit the full potential of induction. All the heat is generated directly within the barrel and remains in the process. The coil’s thermal mass is also eliminated, and coil resistive losses are negligible so the exterior surface is cool to the touch. Barrel heating efficiency approaches 100 % and temperature control response is significantly improved.

Benefits:

Energy savings for barrel heating of up to 70% compared with heater bands

• Additional energy savings - upto 35% more - due to reduced air conditioning load

• Additional energy cost reduction from reduced peak power demand

• Fewer heater failures to cut downtime and maintenance costs

• Immediate cooling and heating response to improve quality and reduce scrap

• Quicker heat-up, typically 2X or more, to boost productivity

• More heating capacity- typically 3X higher wattage into the barrel- eliminates a bottleneck

• Higher barrel temperature capability to mold high-temperature polymers, or metal

• Cool exposed surfaces for increased operator safety

The nXheat™ system uses a high-frequency power supply and helical induction coils to generate heat directly within the barrel wall. A thermal insulating layer is interposed between the coils and barrel to combat heat loss, increase efficiency and improve control response.

The system is available in two forms:

1) all-zone nXheat™ in which induction heating completely replaces conventional heater bands;

2) nXheat-Hybrid™ in which power-saving induction technology heats the barrel’s feed zone while conventional band heaters handle downstream zones.

All-zone nXheat™ delivers maximum savings in power consumption, about 50-70%. It is the ideal system for larger machines with more than three heating zones because of the high value of the reduction in power consumption.

On smaller machines with two or three zones the nXheat-Hybrid™ system can deliver most of the savings of the all-zone system because induction is used in the barrel’s feed zone where the greatest amount of heat input is required to start the melting process. On such machines, which usually have barrels with inside diameters of 50 mm or less, the hybrid system will typically provide a 30 to 50% reduction in power consumption.

In the hybrid system, downstream zones can use either insulated or uninsulated band heaters. Greater energy savings are achieved with the use of insulated band heaters. The same sheet insulation that is used in the induction-heated feed zone can be used to wrap the downstream band heaters. The precision and fast response of induction heating in the feed zone will also substantially reduce temperature overshoot problems that can occur with insulated band heaters.

The system will pay for itself with power cost savings and other cost and quality benefits. These include reduced scrap stemming from less variation in melt temperature and faster response to changes in target melt temperature. The payback period on investment costs for these systems is highly dependent on electricity rates, machine size and production schedule (hours of operation per year). Such a system typically costs about 25-50% of an all-zone system. |

|