Barrier packaging

protects products from infiltration or in some

cases, exfiltration (the passing out from the

container) of contaminants, of flavor, color,

odor, etc., as well as preserving the contents.

Barrier resins are polymers that are used in packaging

to provide a barrier to some unwanted intrusion

in or out of the package. Barrier resins block

passage of several important substances, including

oxygen, moisture, odors, flavors and others. Plastic

barrier packaging has shown significant growth

since the discovery and development of the first

synthetic specialty barrier resin, polyvinylidene

chloride in the 1950s and 1960s. The commercialization

of ethylene vinyl alcohol (EVOH) came a bit later,

in the 1970s. The barrier properties that are

very critical are: Oxygen, Carbon Dioxide and

Moisture. Unfortunately, sunlight and store lighting

cause color fading, vitamin loss, and generally

compromise the most carefully designed product

and can damage branding image and credibility

by low taste or poor visual appearance. For obvious

economic reasons, the food, detergent and cosmetics

industries constantly search for solutions to

extend the shelf life of their products.

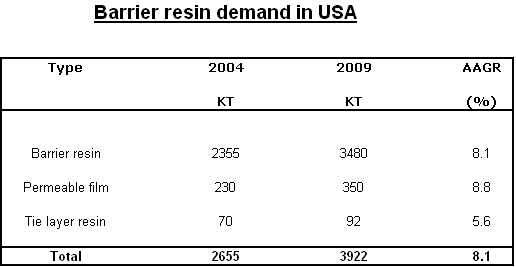

As per a new market research

report from Business Communications, the demand

of barrier resin in USA in 2004 was about 2.7

KT and is expected to grow at 8% to reach about

3.9 KT by 2009. There are 3 basic applications

markets of barrier resin. The largest is food

and beverage packaging, which accounts for more

than 90% of the U.S. market. Other smaller but

important markets include chemical/industrial

products packaging (including automotive gasoline

tanks) and healthcare products packaging such

as blister packaging. There are essentially 3

different types of products in the category of

barrier resin:

- Barrier resin

- Permeable film

- Tie layer resin

- Ethylene-vinyl alcohol (EVOH) copolymers,

the highest oxygen barrier resins are now commercially

produced and most used in the U.S. for food

packaging.

- PCTFE, the fluoropolymer polychlorotrifluoroethylene,

the highest moisture or water vapor barrier

resin is mostly used for pharmaceutical blister

packaging (PBP) for drugs, which are very moisture

sensitive.

- Nitrile resins, copolymers of acrylonitrile

(AN) with methyl acrylate (MA) are used in food,

chemical/industrial and healthcare packaging

- Polyamide (nylon) barrier resins, primarily

oriented nylon 6, is mostly used in food packaging,

and is also used in chemical/industrial and

healthcare product packaging.

- Thermoplastic polyesters, primarily PET is

by far the largest market since we include the

use of PET as a carbon dioxide barrier resin

in beverage bottles. This market is expected

to continue to constitute more than 90% of the

barrier resin market as it grows at an AAGR

of 8.3% through the forecast period.

Tie layer resins are adhesive

resins used to bond together dissimilar resins

in the increasingly popular multilayer barrier

packaging structures (MLS). Typical tie resins

are copolymers of ethylene with vinyl acetate

(EVA copolymers) or an acrylic comonomer. These

tie layer resins are expected to grow at 5.5%

from 75 KT in 2004 to almost 100 KT in 2009.

Trends in the barrier plastic packaging market

include the continuing development of more complicated

and sophisticated multilayer barrier structures,

using more but often thinner layers. Perhaps

the most exciting ongoing development is the

multifaceted effort to increase the barrier

properties of PET to make it a suitable material

for packaging beer. Several new methods have

been developed and now are being tested. This

market could present a significant new opportunity

for PET in barrier packaging.

Current barrier packaging plastics are good,

but problems that restrict their use or hinder

their growth remain in many applications. These

include:

- High Cost:

Cost of barrier resins

is almost always higher than the cost of a

simple monolayer plastic package of LDPE or

LLDPE.

-

Susceptibility to contamination

or degradation especially by moisture:

EVOH is the best example of this problem,

since its hydroxyl groups give it good barrier

qualities but also make it susceptible to

hydrolysis. As a result, EVOH only can be

used as an inner layer in a MLS.

-

Recylcing or Disposal problems:

Since most barrier packaging contains more

than one type of plastic, recycled is difficult.

-

Challenges from competing

materials:

Silicon oxide glass coatings can provide a

superior barrier.

|